The European GEMSTONE project has funded nearly twenty innovation projects developed and implemented by European companies. These projects have all led to the development of innovative solutions for the green transition in manufacturing.

As the GEMSTONE project draws to a close, the partners have decided to organize a competition between the projects to allow the public to choose the project that most appeals to them. The 9 innovation projects that submitted their applications are now revealed to you, and it’s your turn to support THE project of your choice! The winner will receive a financial prize of €3,000.

The rules are simple:

- You review the innovation projects.

- You vote for THE project of your choice via the link provided at the bottom of the page. Please note: you are only allowed one choice!

The Projects:

GA001

Reprex

Customized 3D Orthopedics treatment, but recycled from the previous and to next patients.

Customized treatment permits to better take care of citizens, from the childhood until the elderly. However, those are demanding in time and resources, are they cannot be reuse by the next patient.

3D printing of those solutions permit a more accurate and easier process for the orthopedics, permitting to focus on the patient instead of the production. Create It Real (CIR) already provided those solutions in more than XX countries. But these parts, used during a limited period, end in the waste. FADDTORY focused on the recycling of different materials from 3D printing area as PP and TPU, to traditional extruded PP. Then everything is possible again!

Even if the technological aspects are now close to be controlled, the acceptation of the approach and its implementation are still ongoing, as it is demanding some extra steps to orthopedics in terms of collecting, sorting and logistics. But this challenge is our main focus now, developing new business models to bring a win-win solution!

GA004

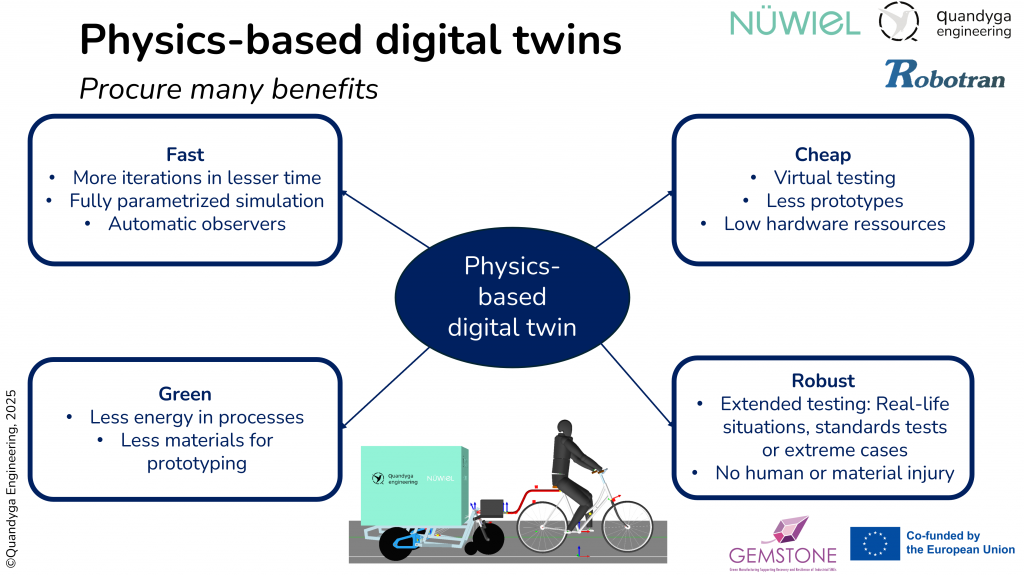

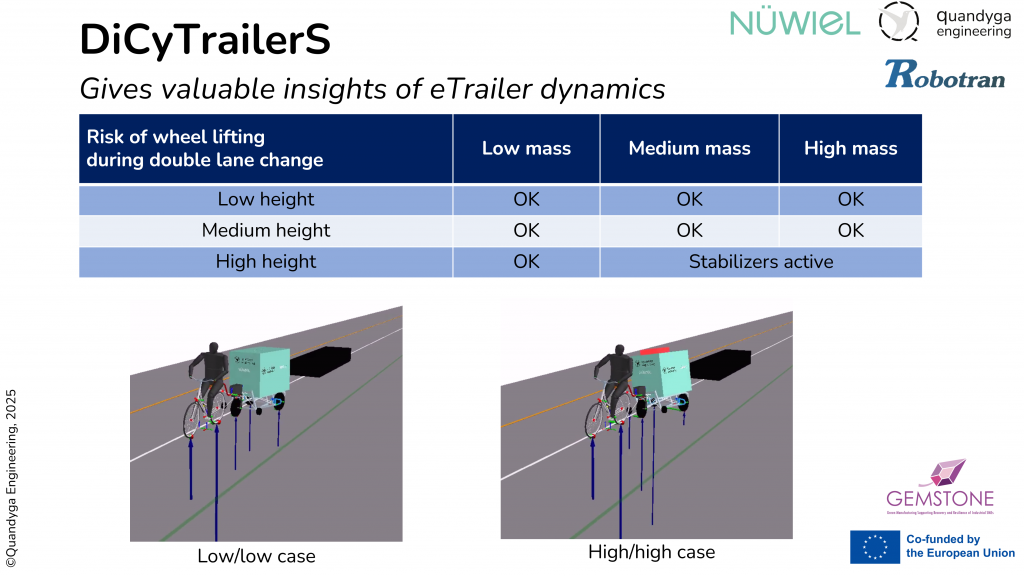

DiCyTrailerS – DIgital CYcle TRAILER Simulator

DiCyTrailerS is revolutionizing green urban mobility with a powerful digital twin that helps to design smarter, safer, and more sustainable eTrailers—cutting emissions, saving resources, and paving the way for greener, quieter cities.

DiCyTrailerS developed an innovative digital simulator to design and test electrically powered cycle trailers. By creating a physics-based digital twin of NÜWIEL eTrailer using Quandyga’s multibody modeling, the project reduced resources required for prototyping, cutting material use and CO₂ emissions. The simulator enables safer, more efficient trailer designs, accelerating green innovation in urban logistics. With real-time firmware integration and validated virtual testing, it enhances manufacturing precision, reduces development time, and supports circular design practices. Looking ahead, Quandyga aims to adapt its digital tool to other mobility sectors, including trucks and trains, amplifying its impact across the EU’s manufacturing landscape. NÜWIEL will leverage the simulator to optimize future eTrailer designs, increase safety and improve overall performance of the system, while contributing to cleaner, quieter, and more sustainable cities.

https://www.linkedin.com/embed/feed/update/urn:li:ugcPost:7269651553500770305?collapsed=1

GA008

MECOTRONICS (More ECOlogic mechaTRONICS)

Improving the energy sustainability of a production system through intelligent control logics and advanced human-machine interaction systems.

The MECOTRONICS project successfully developed and tested advanced strategies for energy efficiency and digital innovation in manufacturing systems. By integrating intelligent control logics and IoT technologies, the project achieved a significant reduction in energy consumption—up to 35% compared to conventional systems—thanks to smart scheduling that stops unnecessary machine operations and improves human-machine interaction. Operators are now better supported through real-time notifications and fault management, reducing downtime and increasing overall plant productivity. These results are scalable to full industrial environments, enabling companies to reduce energy waste and improve sustainability across operations. In the future, MECOTRONICS will integrate AI tools to further optimize energy use and predictive maintenance, representing a replicable model for driving the green transition in the European manufacturing industry.

GA011

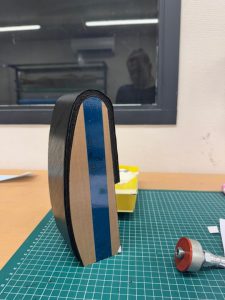

Creation of a reuse chain for composite waste to manufacture accessible prostheses

Reducing energy consumption in the production of running prostheses for amputees made from reused composite materials.

This project rises to the challenge of making sport more accessible to thousands of amputee people while reducing its environmental footprint. Two French companies, Sisco Composites and Hopper, based in different regions, have joined forces to reuse composite material offcuts from the aeronautical industry to manufacture sports prostheses that will enable more amputees to return to sport thanks to more accessible products. While reusing materials considered to be waste is an important part of the project, it is also possible to modify the manufacturing processes because the mechanical requirements are different to those in aeronautics. The Gemstone project has reduced energy consumption during the production curing phase by 22–38% by changing the curing parameters, while maintaining sufficient performance for prosthetic parts. These findings will facilitate the production of running blades and two new prosthetic sports feet over the coming year.

https://145630718.hubspotpagebuilder.eu/sisco-hopper-gemstone-project

GA012

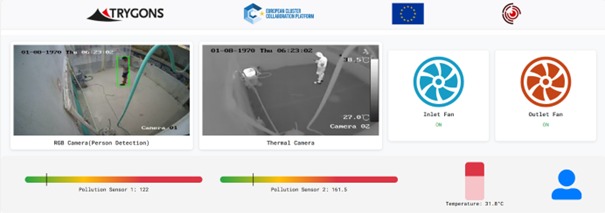

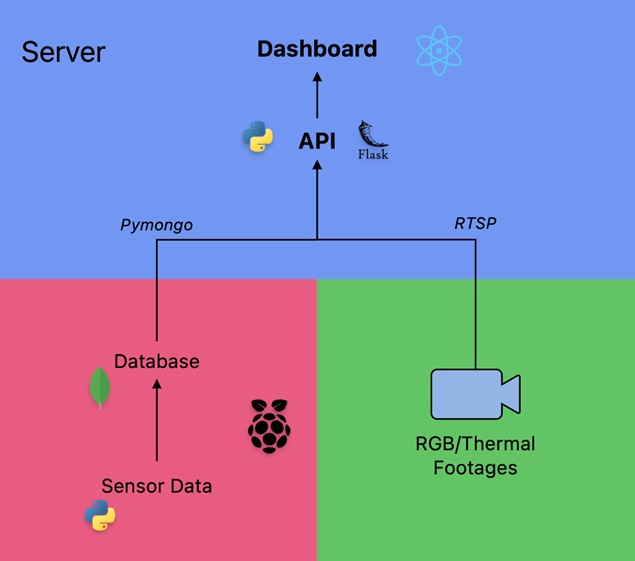

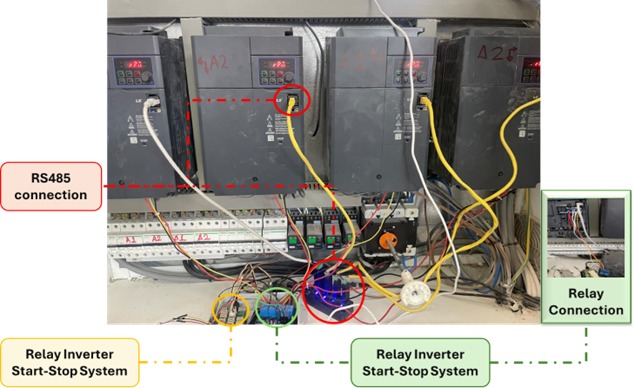

AIvent [AI-driven control of Industrial Oven Ventilation and Energy Consumption Reduction]

AIvent turned an invisible energy drain into a clear win for sustainability, proving how AI can cut waste and promote a healthier working environment in real industrial settings.

AIvent tackled the often-overlooked problem of always-on industrial ventilation by introducing an AI-powered system that

dynamically adjusted fan operation and heating based on real-time pollution levels and human presence. Fully deployed in TRYGONS’ live production line, AIvent achieved a 70% reduction in energy consumption, tripled projected cost savings, and significantly

improved air quality, far exceeding our original expectations and fostering a healthier, more sustainable working environment. Co-developed through a strong cross-border collaboration with iThermAI, AIvent stands as a clear example of how smart, targeted

innovation can drive the green transition in manufacturing. Building on this success, we have begun expanding AIvent’s capabilities by integrating it with other AI applications and digital twins across the production line, and by introducing new sensors for enhanced environmental monitoring, advancing our vision of a fully digitized, intelligent shopfloor.

https://www.linkedin.com/posts/gemstoneproject_euroclusters-activity-7153325222769614849-SSZw/

GA039

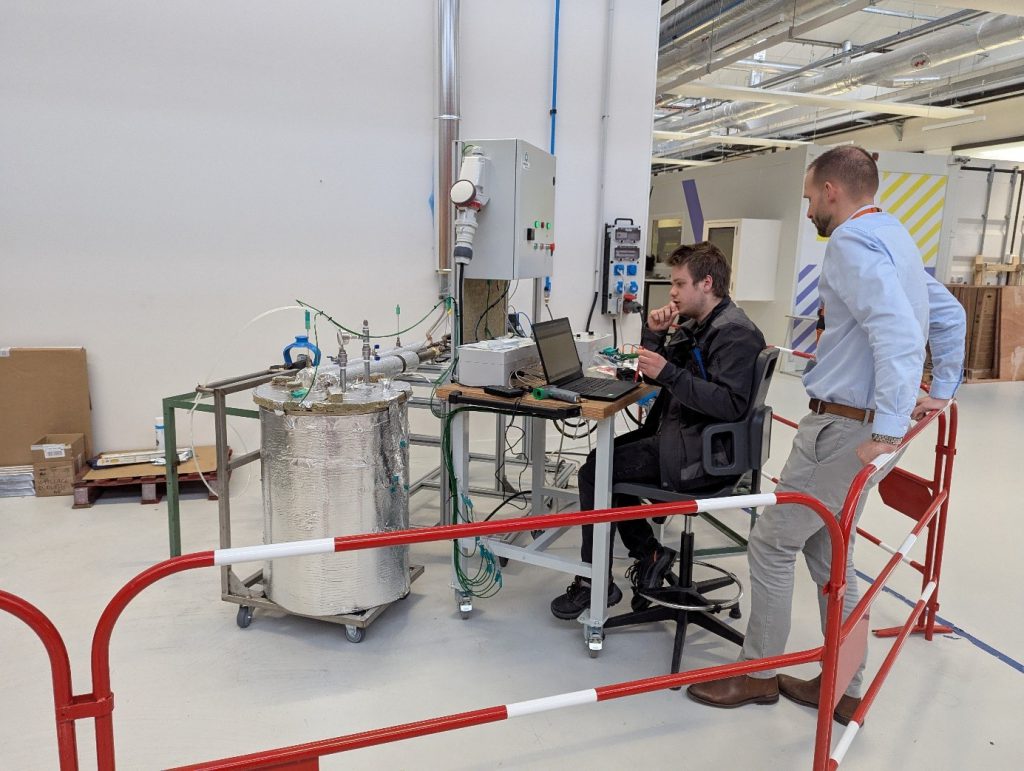

BHEE – High Energetic Efficiency Battery

A massive energy storage solution based on molten aluminum for dual applications, supplying electricity and heat to decarbonize industries process.

The BHEE project demonstrated the feasibility of our aluminum Carnot battery solution. This first Proof Of Concept (POC) allowed us to identify and solve a high number of problems like corrosion by liquid aluminum and thermal insulation at high temperatures. We were able to highlight the stages of liquefaction and solidification of aluminum, as well as the energy supplied and recovered. We were also able to quantify the heat loss and find effective solutions for new POCs. The project was a real milestone that has now enabled us to work on developing a new POC on a scale 10 times larger. We are now bringing together various companies (end users, technology providers, etc.) to form a consortium to create a new collaborative project.

GA049

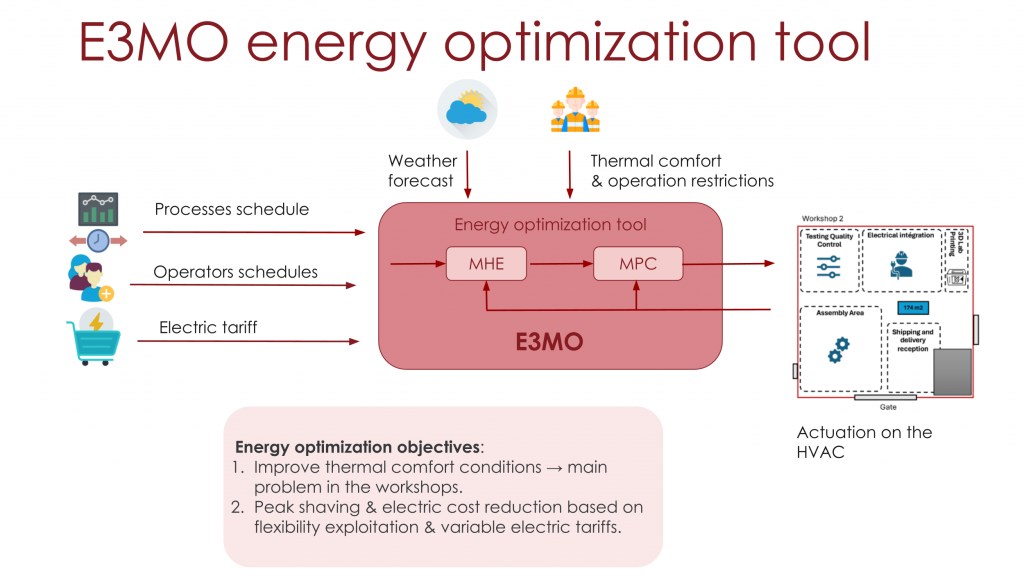

Enhancing Energy Efficiency and Manufacturing Optimization (E3MO)

E3MO brings data-driven energy optimization to manufacturing workshops through digital twins, cutting consumption while improving working conditions.

E3MO developed a digital twin based energy optimization approach for manufacturing workshops, combining real monitored data with predictive models. At OSMOSE, the tool demonstrated potential to reduce energy use by 44%, energy costs by 43%, and thermal discomfort by 90%, directly contributing to lower emissions and improved working conditions. The solution supports the green transition by enabling data-driven control of HVAC systems, the main energy consumers in many plants. Its modular architecture and transnational collaboration between R2M (Spain) and OSMOSE (France) ensure high replicability across Europe. Future plans include automation, further industrial validation, and scaling to additional sites under national and EU-level initiatives, reinforcing its role in decarbonizing the manufacturing sector.

GA050

Autonomous Bluetooth® LE environmental sensor

Monitor indoor air quality, temperature and humidity with no battery change thanks to our latest sensor powered with ambient light!

Our project offers a smart air quality monitoring solution that reduce electronic waste and energy use. We have developed a compact sensor that runs on indoor light instead of disposable batteries.

It tracks key data like air quality, temperature, and humidity—helpful for schools, offices, farms, or warehouses. The sensor uses very little energy, thanks to custom software from BLINQY, and solar film from DRACULA TECHNOLOGIES that captures light, even in low conditions. It works 24/7 with just a few hours of light each day. This means fewer battery changes, less maintenance, and less waste.

Our goal was to make technology more sustainable, more affordable, and easier to use over time. The result is a reliable, battery-free device that helps people monitor their environment while reducing impact on the planet.

It’s a step forward for greener buildings, smarter logistics, and cleaner air.

https://blinqy.be/gemstone-co2

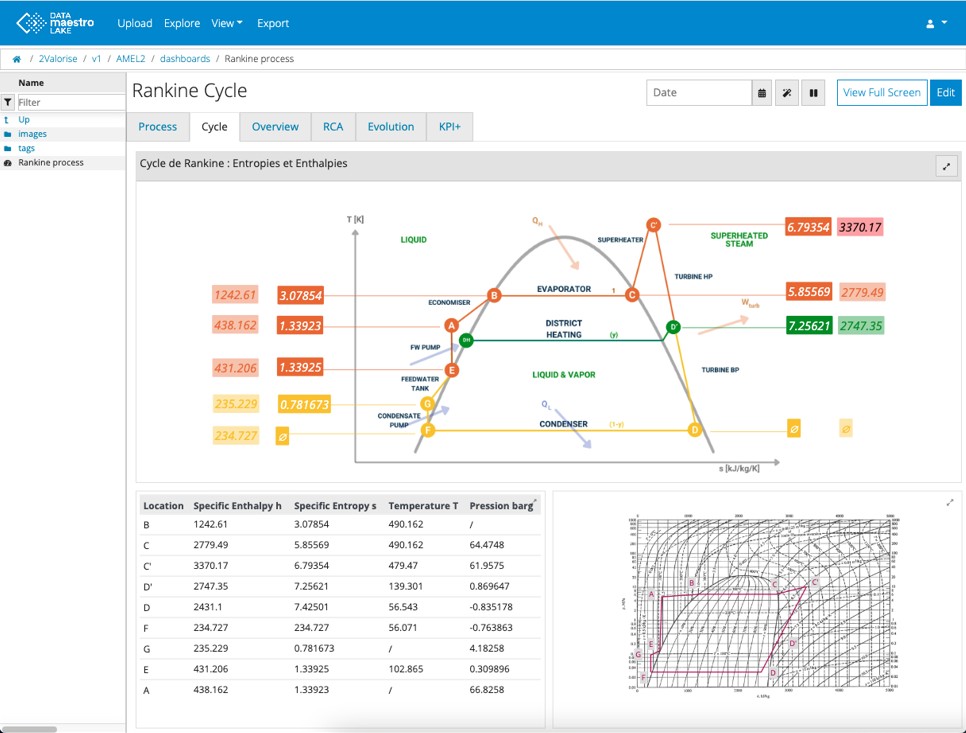

GA052

Digital Asset Template for Cogeneration Energy Efficiency

This pioneering project introduces a smart, scalable solution for monitoring combined heat and power plants, supporting the green transition of the manufacturing sector with measurable economic and environmental benefits.

This project delivers strong economic, environmental, and societal gains via a real-time, template-based monitoring tool for combined heat and power (CHP) plants. Co-developed by PEPITe and 2Valorise, it enhances reliability, OEE, and energy efficiency, while reducing emissions, costs, and staff workload through no-code analytics. Easily scalable across factories, over 20 units are being targeted. Actively used by 2Valorise, the tool is continuously evolving through our ongoing partnership, aiming to support a greener, smarter manufacturing sector.

Have you made your choice? Now it’s your turn to vote via this link: https://strawpoll.com/wAg3QzLzOy8. Deadline: 23/06, 5pm (CET).